Why CNC Equipment Manufacturers Need RFID Integration

CNC machine manufacturers face the following pain points:

- تآكل الأداة والتعرف الخاطئ: Manual tool calibration errors cost manufacturers more than $50,000 في السنة.

- Untraceable Production Batches: Compliance failures due to missing part history.

- Unplanned Downtime: Unplanned tool changes reduce productivity by 20-30%.

RFID integration solves these challenges by:

- Automating tool lifecycle tracking.

- Enabling real-time data capture for auditing.

- Predict tool failures before they happen.

Your Competitive Advantage:

Deliver Industry 4.0-ready CNC systems with embedded RFID.

Get premium pricing for reduced customer downtime.

Key CNC Challenges Solved with RFID Integration

Key CNC Challenges Solved with RFID Integration

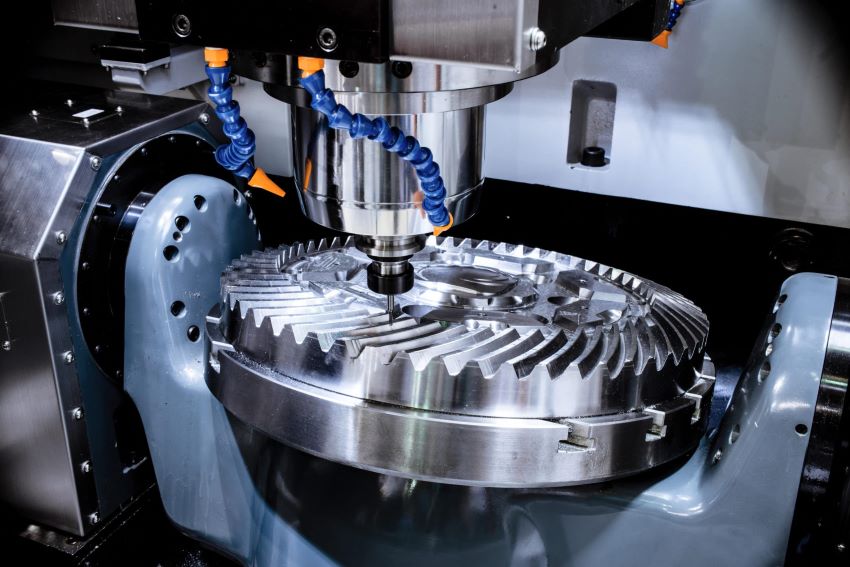

1.Tool Error Identification and Wear Management

Problem: Manual tool setup errors lead to scrapped parts and rework.

حل RFID:

- Embed high-temperature RFID tags (e.g., Mini RFID Tag) directly into toolholders.

- Automatically read tool ID and usage time with RFID readers (e.g., HY-RU6403 Fixed Reader).

2.Compliance and Traceability Gaps

Problem: Manual logs do not meet ISO 9001 or AS9100 traceability requirements.

حل RFID:

- Store machining parameters, batch IDs, and maintenance logs on high-memory UHF tags.

- Automatically synchronize data with MES/ERP systems during tool changes.

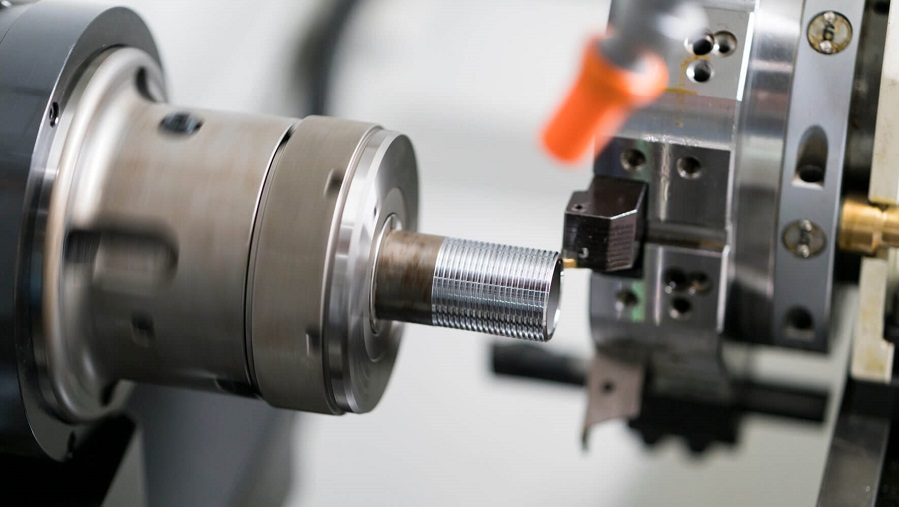

3.Unplanned downtime due to tool failure

Problem: Unpredictable tool wear results in $10,000 per hour of lost production.

حل RFID:

- Track tool lifecycles and trigger predictive maintenance alerts via RFID.

- Integrate with PLC to automatically pause machine when tool life is nearing end.

Top RFID Tags for CNC Machine Integration

Top RFID Tags for CNC Machine Integration

| Tag Model | التردد | قوة التحمل | Ideal CNC Use Case |

|---|---|---|---|

| العلامة مرنة ذات تردد فوق العالي | HF (13.56 CH4) | المعادن المضادة, 120°C rating | Tool holders in milling centers |

| تتفاعل عمله العلامة | التردد فوق العالي (860-960 CH4) | IP68, Long life | Large fixture tracking |

| RFID PPS Tags | HF | Heat-resistant (200° C) | High-speed spindle tools |

| وتتفاعل المعادن العلامة | التردد فوق العالي | وعره, vibration-proof | Pallet & workpiece tracking |

How CNC-RFID Integration Works: Technology Breakdown

1.Hardware Setup:

- علامة RFID: Mounted on toolholder, pallet, or fixture.

- قارئ RFID: Mounted on tool changer or machine door (على سبيل المثال. SICK CLV640).

- CNC controller: Processes RFID data via Ethernet/IP or PROFINET (على سبيل المثال. Siemens 840D).

2.Data flow:

A tool with an RFID tag enters the spindle.

A reader scans the tag and sends the tool ID + usage data to the CNC controller.

The controller cross-checks the data with preset parameters to:

- Block incorrect tools.

- Adjust machining paths to compensate for tool wear.

- Log data to generate compliance reports.

3.Software integration:

- Middleware: System service provider platform links RFID data to CNC logic.

- API: Custom scripts synchronize RFID data with CAM software (على سبيل المثال. Mastercam).

Case Study: Automotive CNC Machining

A CNC machine manufacturer integrated tags with a Mazak SmoothX controller to:

Reduce tool setup errors in engine block production from 8% إلى 0.2%.

Reduce compliance audit time by 75% with RFID automated reporting.

Ready to upgrade your CNC system?

Ready to upgrade your CNC system?

Don’t lose customers due to preventable tooling errors and downtime. We help CNC manufacturers use RFID to ensure their machines stay competitive. اتصل بنا: Test free RFID tags optimized for your tools and fixtures.

We provide:

RFID Integration for CNC Machines

Best RFID Tags for CNC Tool Tracking

UHF RFID Tags for CNC Production Automation

FAQs:

Q: Will RFID interfere with CNC machine operations?

A: لا! Anti-metal tags are designed for EMI resistance in machining environments.

Q: How can I retrofit RFID into older CNC models?

A: Seamless integration with legacy controllers using plug-and-play kits.