$2.3M Wake-up Call: BY’s Tool Management Crisis

En 2022, BY faced a $2.3 million FAA fine for flight delays caused by wrenches left on planes. Investigators found:

- 28% of production delays are related to missing tools

- Machinists waste 45 minutes per day looking for tools

Industrial-grade RFID tags: Survive extreme manufacturing conditions

4 key tests for aerospace environments

| Prueba | Estándar | RFIDHY Performance | Industry Average |

|---|---|---|---|

| Cutting Fluid Resistance | ISO 18184 | 3,000hrs no corrosion | 1,200hrs |

| Vibration Endurance | MIL-STD-810G | 15G/40hrs passed | 8G/24hrs |

| High-Temperature | SAE AS6008 | 200°C for 72hrs | 150°C threshold |

| EMI Resistance | IEC 61000-4-3 | 20V/m immunity | 10V/m tolerance |

BY’s RFID Implementation Blueprint

Smart Tool Identification

- Carbide Tool Tags: Withstands CNC Coolant Spray (IP68 =Grade)

- Magnetic base tag: attaches to irregular tools (15N holding force)

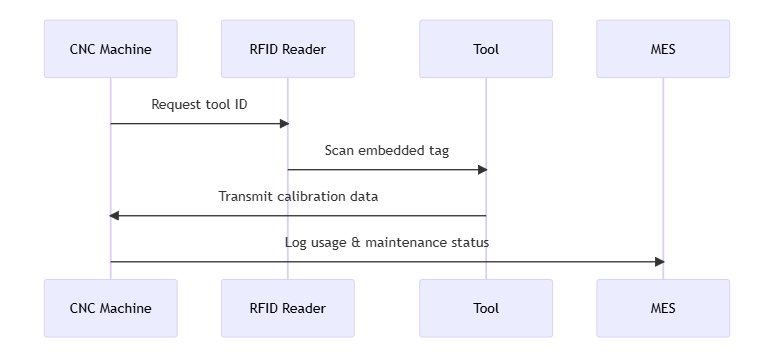

Real-time CNC integration

18 minutes reduction in setup time per shift

BY Factory Measurable Results

| Metric | Pre-RFID | Post-RFID | Improvement |

|---|---|---|---|

| Tool Search Time | 45 minutos | 2 minutos | 96% |

| Lost Tool Incidents | 127/mes | 24/mes | 81% |

| Maintenance Costs | $2.8M/year | $1.6M/year | 43% |

| Audit Compliance | 72% | 99.3% | +27.3 pts |

Manufacturer Implementation Roadmap

Tool Tagging Strategy

- Priority 1: High value and safety critical tools (torque wrenches, calipers)

- Priority 2: High mobility items (portable drills, metros)

Infrastructure Deployment

UHF readers installed in 8 key areas:

- Key Areas: CNC Stations, Tool Racks, Quality Checkpoints

Integración de sistemas

SAP PM Module Compatibility

Real-time dashboard with outage alerts

[Request Factory Assessment] Get your custom RFID tool management proposal.