Cómo la tecnología RFID impulsa la metalurgia y la automatización de maquinaria?

El $2.5 La industria metalúrgica y de maquinaria mundial está bajo presión para aumentar la productividad mientras mantiene estrictos estándares de calidad. RFID (Identificación por radio frecuencia) La tecnología se ha convertido en una piedra angular de esta transformación, con 63% de los fabricantes que adoptan soluciones RFID. Para proveedores de servicios de sistema, this trend presents a strategic opportunity to deliver high-value automation system enhancements. Here is your actionable guide:

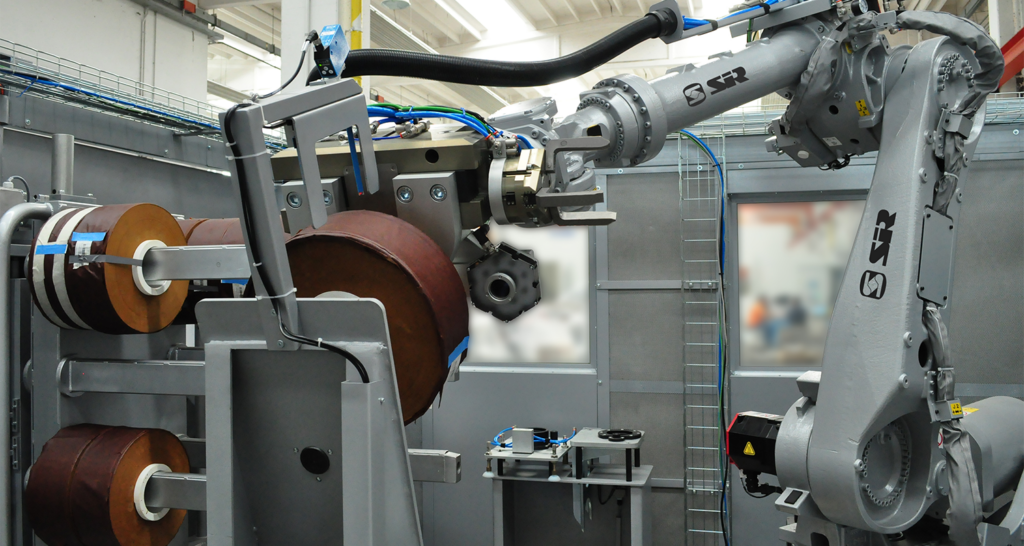

RFID Application Scenarios in Metalworking

1.Raw Material and WIP Tracking

- Aplicación: RFID tags on steel coils or aluminum billets enable automated inventory systems to track material grades and heat numbers.

- Caso: A leading aerospace supplier reduced material mix-ups by 89% using RFID-tagged titanium billets.

2.CNC machining optimization

- Tool management: RFID tags on cutting tools automatically record usage time, triggering a replacement alarm when the service life reaches 90%.

- Job setup: Haas machines use RFID-tagged workpieces to load preset CNC programs, reducing setup time by 45%.

3.Welding and assembly lines

- Process verification: RFID tags store welding parameters (amps/second) to ensure compliance with AWS D1.1 standards.

- Component matching: Caterpillar’s assembly line uses RFID to verify the compatibility of hydraulic valves with engine blocks.

4.Quality control and traceability

- Dimensional data recording: RFID tags associated with CMM (coordinate measuring machine) results enable full GD&T traceability.

- Recall prevention: Bosch Rexroth achieves 100% failure traceability of hydraulic pumps using RFID-based production records.

5.Maintenance and Safety

- Equipment Monitoring: RFID sensor tags on press brakes track vibration patterns, predicting bearing failures 3 weeks in advance.

- PPE Compliance: Tags on hard hats ensure only certified workers enter high-risk areas.

Non-automated scenarios and RFID opportunities

| Proceso manual | Solución RFID | Impacto |

|---|---|---|

| Handwritten work | RFID-enabled digital work instructions | Eliminar 75% paper reporting delays |

| Manual asset location checks | Real-time RFID RTLS | Reduces search time by 80% |

Basic RFID system components

1.Hardware

- Etiquetas: Anti-metal UHF RFID tags, Variantes de alta temperatura

- Lectores: Industrial-grade fixed readers (IP67) and handheld RFID reader/writer devices for shop floor use

- Antena: RFID near-field antenna for close-range metal surface reading

2.Software

- Middleware (Middleware): OPC-UA integration with PLC (Siemens, Fanuc)

- Analítica: Predictive maintenance dashboard linked to MES system

3.Integraciones

- ERP connectivity (SAP, Oracle)

- Retrofitting old machines with IoT gateways

Recommended RFID tags for metal processing

| Aplicación | Etiqueta recomendada | Características clave |

|---|---|---|

| Metal Part Tracking | UHF Flexible Anti-Metal Tag | Direct metal mount, -40° C a + 200 ° C |

| CNC Tool Holders | HF ICODE SLIX Label | 8mm read range in metal environments |

| High-Temperature Areas | RFID Tag HY-HT4836 | 250°C continuous, IP69K washdown |

| Small Components | Etiqueta RFID ultra pequeña UHF | 12x3mm, embeddable in fasteners |

Cumplimiento de normas: ISO 15693

Ofrecemos:

RFID solutions for CNC tool management

RFID tracking in welding automation

Custom RFID systems for metal stamping

UHF RFID tags for heavy machinery parts

Cost-effective RFID for small machine shops

Why work with industrial RFID experts?

Metalworking customer requirements:

✅ AS9100/IATF 16949 cumplimiento de normas: audit-ready data tracking

✅ Heavy industry expertise: understanding coolant/fouling challenges

✅ Global scalability: multi-plant deployment capabilities

“5 RFID Strategies to Improve Machining Profitability”