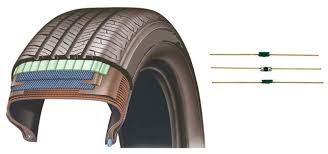

Automobile tire RFID (Identification par radiofréquence) is a technology that uses radio waves for data transmission and identification. It is applied in automobile tires to achieve the following functions:

Tire identification: Each tire has a unique RFID tag that can record and store tire production information, modèle, specification, date de production, factory code and other data.

Surveillance en temps réel: By cooperating with the on-board RFID reader, real-time monitoring of tires can be achieved. Including tire pressure, température, wear degree, etc., these data can be transmitted to the on-board system in real time to help drivers understand the condition of tires in a timely manner and avoid safety hazards.

Life cycle management: RFID technology can record the entire life cycle of tires from production to scrapping, including production, transport, installation, utilisation, maintenance and replacement. This helps to improve the efficiency and accuracy of tire management and extend the service life of tires.

Anti-theft and anti-counterfeiting: Each RFID tag has a unique identification code that is difficult to copy, which can effectively prevent tires from being stolen or counterfeited.

Optimize inventory management: Using RFID technology in tire warehouses can quickly and accurately carry out tire storage, outbound storage and inventory, improving inventory management efficiency.

The application of RFID technology in automobile tires not only improves vehicle safety and management efficiency, but also brings a lot of convenience and commercial value to fleet management, tire manufacturers and retailers.