RFID בייצור רכב

The UHF RFID technology application plays an important role in the automotive field. כעת, smart manufacturing has become a hot spot in the global industry. In the current manufacturing industry, the application of RFID technology has a better policy soil. The tags and chips prices are showing a trend of declining, while the types and performances have kept rising. לכן, this has also promoted more RFID in the manufacturing field. Application in the link. Including warehouse management, process management, and distribution supply chain and so on.

Using RFID technology to promote manufacturing enterprises to achieve “standardization”.

Also intelligent upgrades, lower production costs, flexibly respond to market changes, and better meet customer needs.

RFID in automotive manufacturing also in a good development opportunity. Through the simple automatic identification UHF RFID technology. We realize the object information accurate and rapid identification. And the back-end MES system can make scientific decision-making. Thereby improving the enterprise production efficiency. Improving the organization, shortening the production cycle, and improving the enterprise comprehensive competitiveness.

Automobiles are relatively precise manufacturing

And tRFID in automotive manufacturing processes and manufacturing processes are more complicated. But in general, we can divide it into four major processes: stamping, welding, painting and final assembly. The automobile manufacturing industry has developed to this day. It is very mature, and the manufactured cars are getting more and more high-end. And their performance is getting better and better. אבל למעשה, there are still some inevitable problems in its four manufacturing processes. Or we can say that there is room for improvement.

Workshop sensitive factors

Stamping workshop: RFID in automotive manufacturing Stamping parts are raw materials. And the supply and demand balance directly affects production and productivity efficiency. Lack of effective management methods, inaccurate inventory data, easy to waste productivity, and even affect production. 2. Spray workshop: The paint workshop has harsh working conditions, טמפרטורה גבוהה, אבק, and strong electromagnetic interference. Which are critical to the body color and production process judgment. 3. Assembly shop: the same station, different cars types , different parts and even assembly time for assembly. The current station body information identification is helpful to the production process and scientific scheduling guidance. To balance the assembly time, שפר את היעילות.

פתרון

Digital workshop: we installed Stamping and welding תגיות אלקטרוניות של RFID on the transferring stamping parts material racks. And RFID readers are installed at key nodes in each workshop. In order to realize the products and equipment intelligent communication.

Different workshops have different requirements.

When we implemented the RFID system, it is necessary to formulate different solutions according to these different requirements. לדוגמה, in the stamping and welding workshop. We focus on controlling the production quantity, inventory quantity, and outgoing quantity of stamping raw materials. Realizing accurate statistics can provide data for the intelligent scheduling and scientific decision-making.

The basic realization idea is to install electronic tags on the racks for transferring stamping raw materials.

Deploy RFID reading nodes at the end of the production line, warehouse entry and exit ports. When the stamping parts are produced and loaded on the rack, the information will be automatically written into the rack label to complete the information binding. אחרי זה, it will be transported to the warehouse by a forklift. And then we will install a reading device in the warehouse. By reading the electronic tag, it will locate the raw material information on the rack to complete the storage information record. For the same raw materials, we deploy reading equipment at the exit.

- Digital workshop: painting

התקין RFIDHY RFID tags on the skid of the car body and install RFID antennas on the rolling bed in key positions to identify and track the car body. We call Each RFID antenna an AVI site. Which is responsible for reading and writing RFID tags, and transmits the read information to the PLC through the device. The code carrier records the car body information carried on the skid, including the car body that needs to be painted. The color, car model, car body batch number, car body serial number and so on.

The paint shop is mainly to install electronic tags on the sliding skid of the transport car body.

When we place the car body on the skid, we complete the input of the car body information. We deploy RFID reading nodes on the roller bed in the workshop key position. After the skid transports the car body to a key position, the reading device will read the electronic tag information on the skid to locate the car body identity information of. And transmit the information to the PLC to guide the related operations completion.

- Digital workshop: final assembly

Before the vehicle goes online, the staff installs the initialized RFID tag on the upper surface of the front hood of the vehicle body. Install RFID reading and writing equipment in the subsequent frame assembly, chassis suspension, power-train, interior and exterior integration of the vehicle. And when the body reaches the corresponding station, it automatically scans the body VIN barcode. To complete the production line vehicle monitoring and data collection work.

In the assembly shop, a car body requires many processes, including frame assembly, chassis suspension, power synthesis, ועוד. לכן, by installing an electronic tag on a fixed car body position. It is similar to at the front of the car, this tag will follow the entire assembly entire car body process. And install RFID reading devices at different nodes to guide the process.

Take an example to illustrate the RFID in intelligent manufacturing application mode

This is a job assembly line that can be seen in many manufacturing companies. The raw materials flow in from the front end, through a variety of different process combinations. In a sequential operation mode, to complete the production of a product. באופן מסורתי, we use paper work orders, manual records, or barcode scanning. מצד אחד, it is inefficient. מצד שני, too many human involvements will inevitably make mistakes and cause the production progress to stagnate. לכן, with the help of RFID technology, the electronic tags on raw materials, parts, semi-finished products. And finished products enable production planning managers to quickly locate them. And understand the consumption of raw materials, which will greatly improve the efficiency and quality of production.

באותו זמן, RFID technology can also collect and process product information.

Due to the RFID readable and writable nature

It can provide a constantly updated real-time data stream. Complementing the manufacturing execution system, the RFID information can be used to ensure the correct use of labor, מכונות, כלים, and components. So as to realize paperless production and reduce downtime, and promote the production logistics smooth progress. We may regard this RFID electronic tags use as the information carrier to replace paper work orders. By deploying RFID collection equipment at each station of the production line. The planned information flow management based on intelligent production scheduling as the baseline ensures resource optimization and effective cost control. Completely solve the problems of printing production scheduling; comprehensively solve the tedious management problems. Write all the production process information into the electronic label for storage, and complete the display guidance of the process through the display device of the station terminal.

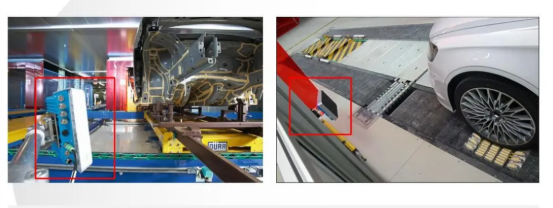

These two pictures show a device installation drawing on the actual site

Which represents the application of two different final assembly links. The basic commonality: through a simple automatic identification technology such as RFID, we can achieve accurate and rapid identification. Help the back-end MES system to make scientific decisions, thereby improving the production efficiency of the enterprise, improving the organization, shortening the production cycle, and improving theenterprise comprehensive competitiveness.