Precision crisis: How a 0.1mm error destroys tens of millions of orders

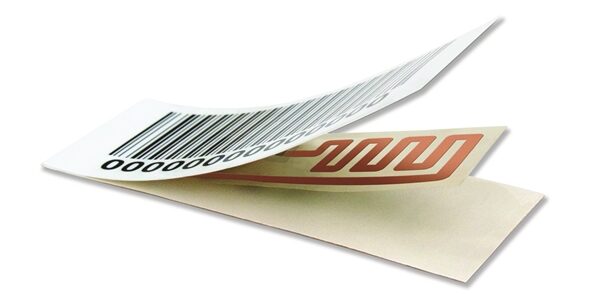

In 2024, an international sports brand failed to read 230,000 smart garments due to a 0.1mm deviation in the line width of the RFID tag antenna. Displayed under the microscope:

- The jagged edge of flexographic printing increases impedance by 47%

- The antenna break point causes the reading distance to plummet from 8 meters to 0.3 Metri

This incident triggered a precision revolution in RFID printing technology:

“When the printing cost of a single product differs by $0.002, every 1μm increase in precision can avoid an average annual quality loss of $1.2 milioni di euro”

-“2024 RFID Manufacturing White Paper”

Six major printing technology parameter showdown

Microscopic battlefield: life and death line under 200 times magnification

| Technology type | Minimum line width | Edge roughness (Ra) | Production speed (m/min) | Yield |

| Flexographic printing | 50μm | 3.2μm | 120 | 92.5% |

| Digital inkjet | 15μm | 1.8μm | 35 | 98.2% |

| Nanoimprint lithography | 5μm | 0.3μm | 8 | 99.8% |

| Laser direct writing | 8μm | 0.5μm | 5 | 99.9% |

| Roll-to-roll electroplating | 30μm | 2.1μm | 200 | 95.7% |

| Vapor deposition | 3μm | 0.1μm | 2 | 99.95% |