astratto: RFIDHY ha lanciato una nuova soluzione tecnologica RFID UHF per tracciare un inventario unificato di biancheria e uniformi per mantenere standard appropriati (Comma) livelli e gestire il processo di lavanderia senza contatto fisico.

RFIDHY ha lanciato una nuova soluzione tecnologica RFID UHF per tracciare un inventario unificato di biancheria e uniformi per mantenere uno standard appropriato (Comma) livello e gestire il processo di lavanderia senza contatto fisico. RFIDHY fornisce una soluzione completamente senza contatto per tutti coloro che gestiscono la biancheria, uniform and laundry process in the wardrobe and housekeeping operations.

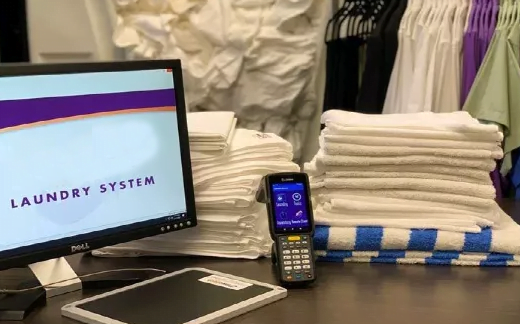

UHF RFID linen system can manage the entire inventory. Con esso, handling linen products and tracking daily activities is simple and safe. According to RFIDHY, record keeping is automated, as long as the linen products are passed through the RFID antenna on the top of the counter, the batch reading station or the portable handheld RFID reader using RFIDHY can be identified. Inoltre, the new solution can also use the UHF RFID uniform system to help employees distribute uniforms, allowing employees to return to work safely without physical contact, and help with uniform transactions.

When implementing the RFIDHY UHF RFID system, five simple steps can help improve performance while ensuring the safety of company employees. The first is labeling. RFID tags are attached to each uniform and linen. These UHF RFID washing tags can be sewn into or heat sealed onto textiles. Their washing cycle is as long as 3 years or 200 volte.

The second step is to create inventory. The information is entered into the system to establish inventory to identify and track each product. RFIDHY said that each item is linked to a unique UHF RFID identification code.

The third step is to maintain the PAR level of the warehouse and allocate uniforms. Once the labeled linen products are sent to the laundry room and warehouse, they will be tracked permanently, and the quantity and type will be recorded at the same time. When uniforms are assigned to employees, electronic signature terminal equipment is used to record employee signatures. These procedures do not require physical contact, and there is no need to use paper to keep records and print reports.

The fourth step is to manage the laundry process. The RFIDHY system tracks the laundry process, mainly by identifying each item sent to the laundry room and each item returned after washing. It does not touch uniforms or linen products, and it can maintain a safe distance from dirty and clean items. Using the RFIDHY system, customers can scan items from a safe distance (fino a 6 Piedi), obtain accurate counts, and automatically update inventory records of items shipped to and from the laundry room.

The last step is non-contact management. From procurement, daily use, laundry to final scrapping, total inventory management is carried out for the entire life cycle of each textile. The system can always accurately know the location of all items. The RFIDHY system provides more than 100 reports detailing all aspects of wardrobe and guest room management, including laundry costs.

The implementation of this system can reduce non-theft-related losses by 100%, reduce labor costs by 50%, and control external laundry fees. Eliminate traditional labor-intensive tasks, such as manual sorting, counting, and recording, to reduce operating costs. Use a portable handheld RFID reader with RFIDHY mobile software without physical contact. The RFIDHY system can be easily configured and expanded to meet customer needs. A typical system installation takes three to five days. Oswald Lares, RFIDHY’ direttore vendite e marketing, Detto: “Continuiamo a innovare per fornire ai clienti soluzioni conformi alle nuove normative igieniche e alle linee guida per l'igiene dell'ambiente di lavoro sicuro. Il nostro sistema aiuta a semplificare e rendere sicuro l'uso della tecnologia RFID UHF.”

The implementation of this system can reduce non-theft-related losses by 100%, reduce labor costs by 50%, and control external laundry fees. Eliminate traditional labor-intensive tasks, such as manual sorting, counting, and recording, to reduce operating costs. Use a portable handheld RFID reader with RFIDHY mobile software without physical contact. The RFIDHY system can be easily configured and expanded to meet customer needs. A typical system installation takes three to five days. Oswald Lares, RFIDHY’ direttore vendite e marketing, Detto: “Continuiamo a innovare per fornire ai clienti soluzioni conformi alle nuove normative igieniche e alle linee guida per l'igiene dell'ambiente di lavoro sicuro. Il nostro sistema aiuta a semplificare e rendere sicuro l'uso della tecnologia RFID UHF.”