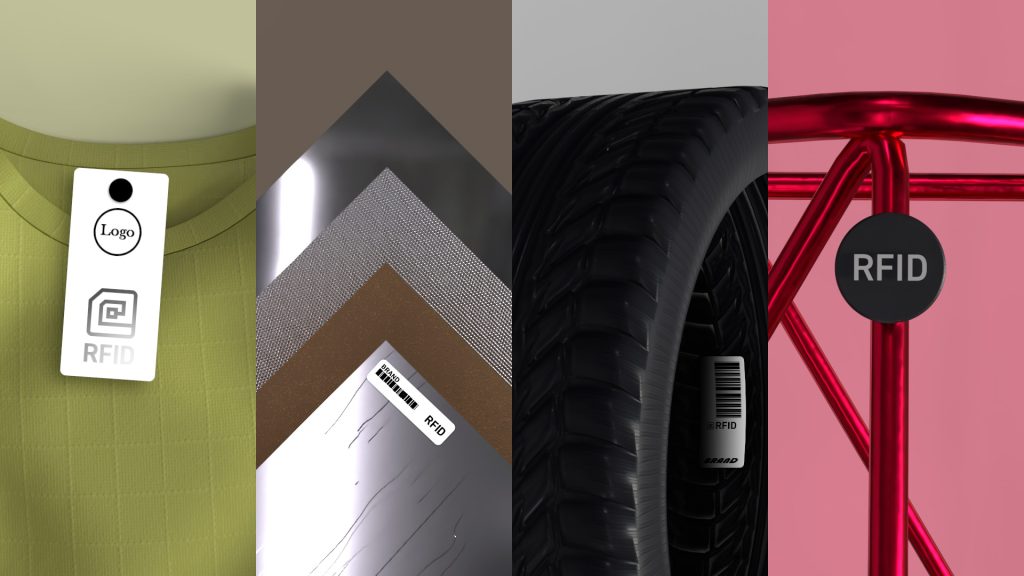

Sconvolgimento del settore: Tre principali forze trainanti per la ricostruzione degli standard di selezione dei tag RFID in 2024

Nel mese di marzo 2024, the 27th amendment to the EU REACH Regulation officially limited the content of bisphenol A in RFID tag adhesives to less than 0.1%. Allo stesso tempo, the density of RFID reading nodes in Amazon logistics centers reached 428 per thousand square meters (fonte: Material Handling Institute, 2024), an increase of 210% Oltre 2021, and the signal collision rate surged to 19%.

New selection logic under double pressure:

Compliance cost ratio increased from 5% A 22% (McKinsey “2024 Manufacturing Report”)

Gli Stati Uniti. Department of Defense Logistics Agency lost $2.7 million due to chemical corrosion of tags (Federal Procurement Data System, 2023)

Parameter 1-3: Environmental adaptability – using military-grade standards to meet industrial requirements

1. The myth of heat resistance is shattered: Analysis of the industrial warehouse accident

In 2023, An industrial warehouse in Canada, used -50°C heat-resistant labels, ma 41% of the labels were delaminated in a -30°C diesel vapor environment. Root cause: The solvent resistance of the polyurethane substrate did not meet the ASTM D543 standard.

Soluzione:

Medical-grade labels must pass the ISO 10993-5 cytotoxicity test

Chemical scenarios strongly require the UL 94 V-0 flame retardant certification to be checked

2. UV kill chain: the US clean energy company photovoltaic power station label failure incident

In the 5GW photovoltaic power station of the US clean energy company, 78% of the substrates of the a series labels were brittle within 18 Mesi. MIT Materials Laboratory proved that the life of labels using DuPont™ Tedlar® PVF film was extended to 7 anni (Solar Energy Materials, 2024).

3. The invisible killer in vibration scenarios: Lessons from Car’s Berlin factory

Y production line did not take into account the 23Hz resonance frequency of the 6-axis robotic arm, resulting in a monthly damage rate of UHF tags as high as 15%.

Parameter 4-6: The golden rule of performance balance

4. Engineering game between size and reading distance

| Manufacturer/model | Dimensioni (mm) | Distanza di lettura (m) | Unit price ($) | ROI cycle (mese) |

| Impinj M780 (UHF) | 50×50 | 12.3 | 0.89 | 14 |

| NXP NTAG424 (HF) | 12×12 | 0.05 | 2.12 | 8 |

5. Strategic choice of memory capacity: inspiration from A perfume brand anti-counterfeiting system

Chanel will use NXP’ 4KB NFC tags in 2023 to store encrypted process data + production logs, increasing the counterfeit product identification rate to 99.6% (Luxury Daily, 2024).

6. The longest distance trap: An aircraft supply chain $12 million tuition fee for the supply chain

The project over-pursued a 15-meter reading distance and selected oversized tags, resulting in an excessive misreading rate of the parts traceability system, which eventually triggered a full system replacement.