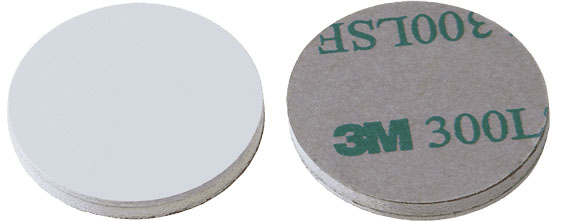

RFID Epoxy Tag

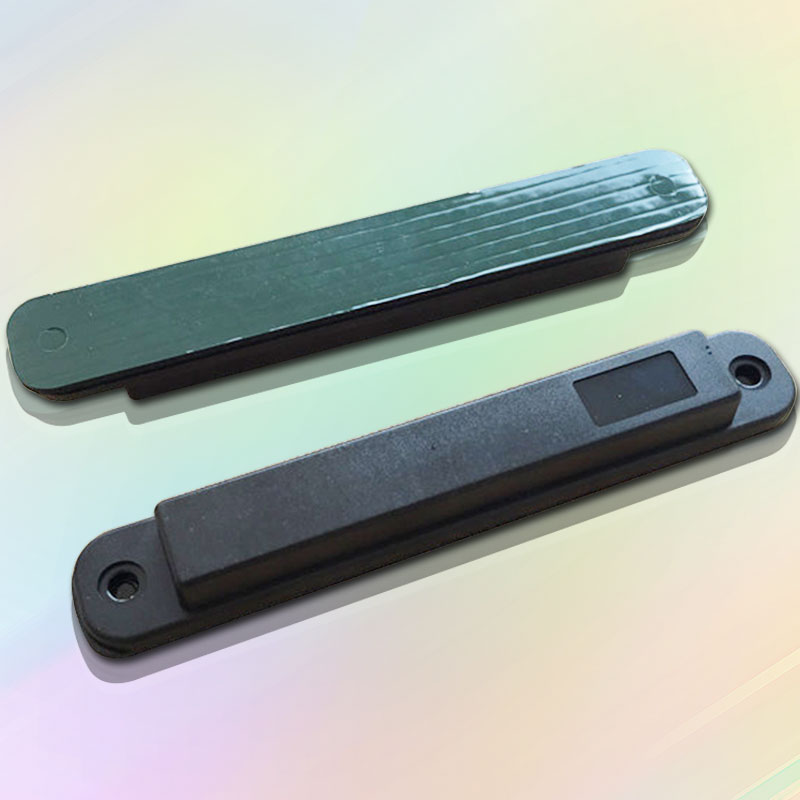

RFID Epoxy Tag is constructed for optimal performance under harsh conditions. They are resistant to fuels, mineral oils, petroleum and salt mist. They repel moisture – even in high temperature, high pressure washes.

Leave your contact detail now to get the latest price!

Design & Applications

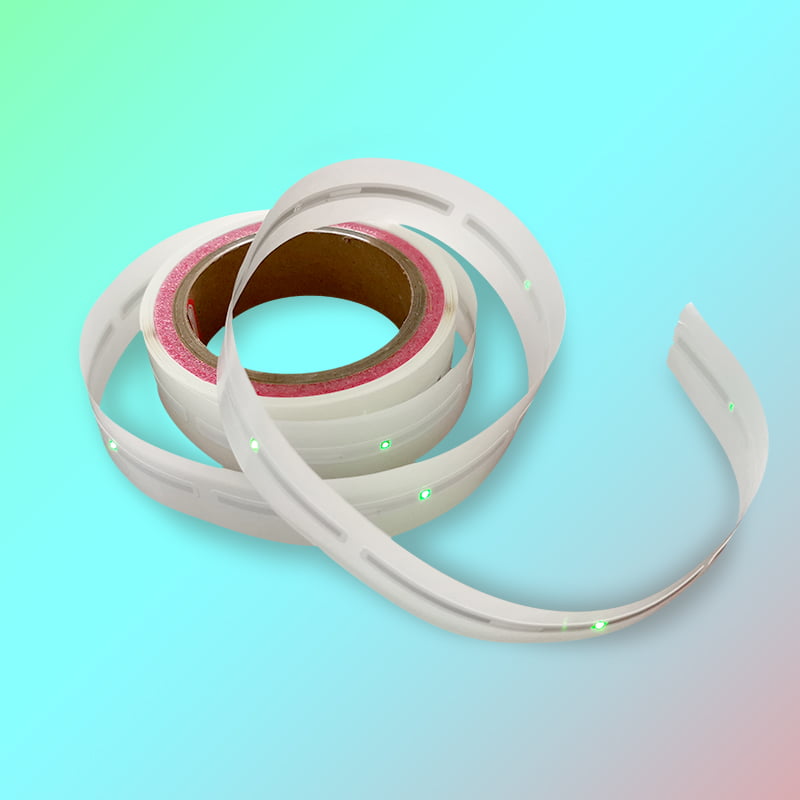

Each micro thin Epoxy Tag device has a smooth surface, which may be imprinted with customized visual codes or artwork.

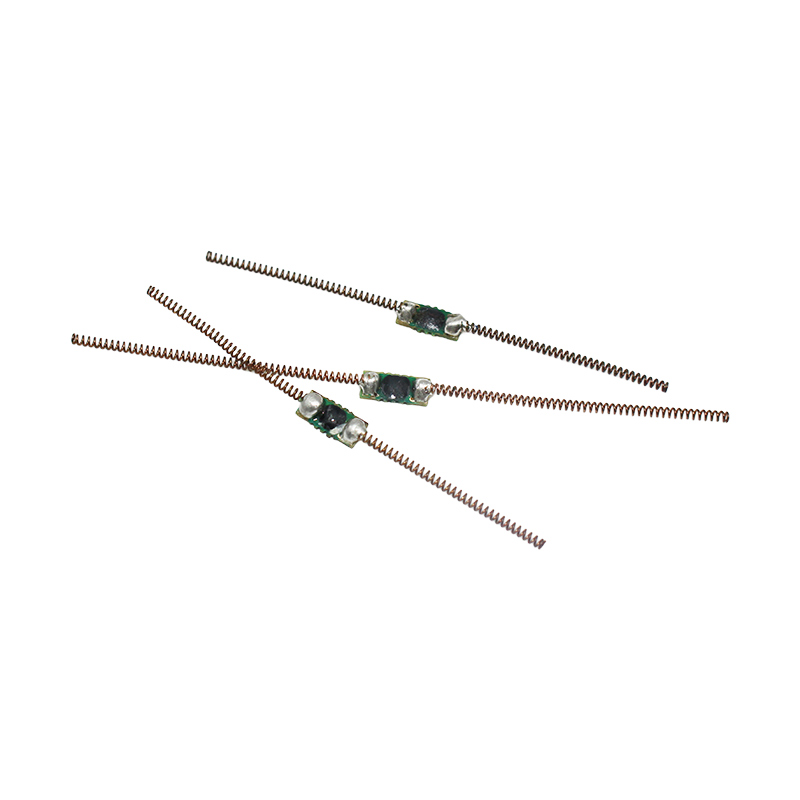

The rfid epoxy tag are available with a broad range of RFID technology, from low frequency 125KHz unique, Atmel T5567, Hitag and high frequency 13.56MHz, Mfiare, I CODE SLI etc, thus providing an optimal solution for different RFID applications.

Key Features

Durable – resists moisture, oils, petroleum; tolerates mechanical vibration and shock

Thermally stable – withstands exposure to temperatures from -40° F to 360° F (-40° to 160° C)

Surface printable – enables tags scannable by both RFID and visual ID readers

Available chip technologies

| Manufacturer | 125 kHz | 13.56 MHz |

| EM Microelectronic | EM4102, EM4200 | |

| NXP | Hitag®1, 2, S | MIFARE Ultralight®, MIFARE® Classic, MIFARE® Classic EV1, MIFARE® DESFire® EV1, MIFARE® DESFire® EV2, MIFARE Plus® I-Code®: SL1, SLI, SLIX, SLI-S, SLIX-S |

| Atmel | ATA5577 | |

| Legic® | Prime:MIM256、MIM1024 Advant:ATC1024、ATC2048、ATC4096 |

可根据要求提供其他 IC。