How RFID Technology Drives Metalworking and Machinery Automation?

, $2.5 trillion global metalworking and machinery industry is under pressure to increase productivity while maintaining stringent quality standards. RFID (Radyo frekansı ile tanımlama) technology has become a cornerstone of this transformation, Ile 63% of manufacturers adopting RFID solutions. For system service providers, this trend presents a strategic opportunity to deliver high-value automation system enhancements. Here is your actionable guide:

RFID Application Scenarios in Metalworking

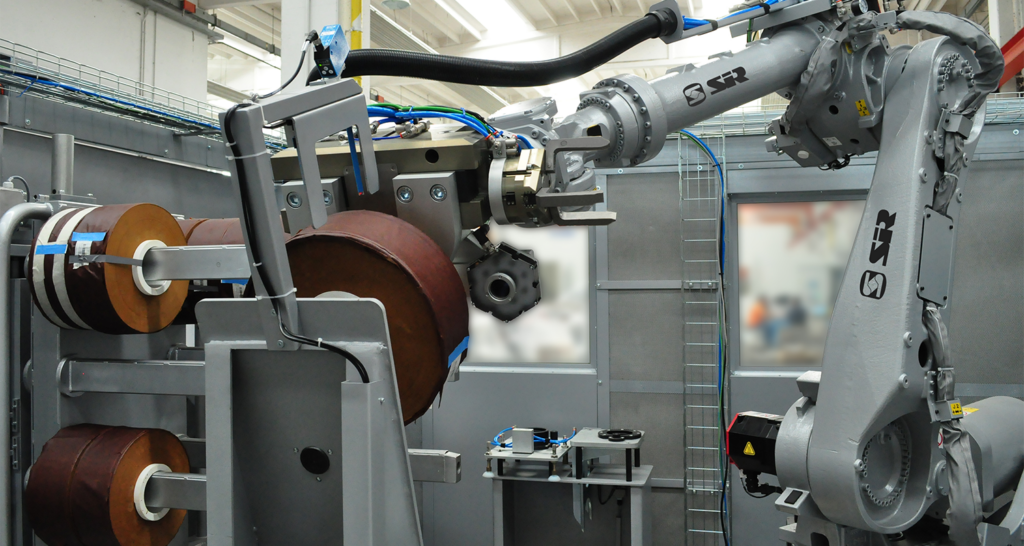

1.Raw Material and WIP Tracking

- Uygulama: RFID tags on steel coils or aluminum billets enable automated inventory systems to track material grades and heat numbers.

- Dava: A leading aerospace supplier reduced material mix-ups by 89% using RFID-tagged titanium billets.

2.CNC machining optimization

- Tool management: RFID tags on cutting tools automatically record usage time, triggering a replacement alarm when the service life reaches 90%.

- Job setup: Haas machines use RFID-tagged workpieces to load preset CNC programs, reducing setup time by 45%.

3.Welding and assembly lines

- Process verification: RFID tags store welding parameters (amps/second) to ensure compliance with AWS D1.1 standards.

- Component matching: Caterpillar’s assembly line uses RFID to verify the compatibility of hydraulic valves with engine blocks.

4.Quality control and traceability

- Dimensional data recording: RFID tags associated with CMM (coordinate measuring machine) results enable full GD&T traceability.

- Recall prevention: Bosch Rexroth achieves 100% failure traceability of hydraulic pumps using RFID-based production records.

5.Maintenance and Safety

- Equipment Monitoring: RFID sensor tags on press brakes track vibration patterns, predicting bearing failures 3 weeks in advance.

- PPE Compliance: Tags on hard hats ensure only certified workers enter high-risk areas.

Non-automated scenarios and RFID opportunities

| Manual Process | RFID Çözümü | Impact |

|---|---|---|

| Handwritten work | RFID-enabled digital work instructions | Orta -dan kaldırmak 75% paper reporting delays |

| Manual asset location checks | Real-time RFID RTLS | Reduces search time by 80% |

Basic RFID system components

1.Donanım

- Etiketler: Anti-metal UHF RFID tags, high temperature variants

- Okuyucu: Industrial-grade fixed readers (IP67) and handheld RFID reader/writer devices for shop floor use

- Anten: RFID near-field antenna for close-range metal surface reading

2.Yazılım

- Middleware (Orta Katman Yazılımı): OPC-UA integration with PLC (Siemens, Fanuc)

- Analytics: Predictive maintenance dashboard linked to MES system

3.Integrations

- ERP connectivity (SAP, Oracle)

- Retrofitting old machines with IoT gateways

Recommended RFID tags for metal processing

| Uygulama | Recommended Tag | Temel özellikleri |

|---|---|---|

| Metal Part Tracking | UHF Flexible Anti-Metal Tag | Direct metal mount, -40°C ila +200°C |

| CNC Tool Holders | HF ICODE SLIX Label | 8mm read range in metal environments |

| High-Temperature Areas | RFID Tag HY-HT4836 | 250°C continuous, IP69K washdown |

| Small Components | UHF Ultra Small RFID Tag | 12x3mm, embeddable in fasteners |

Uyumlu -luk: ISO 15693

Sunuyoruz:

RFID solutions for CNC tool management

RFID tracking in welding automation

Custom RFID systems for metal stamping

UHF RFID tags for heavy machinery parts

Cost-effective RFID for small machine shops

Why work with industrial RFID experts?

Metalworking customer requirements:

✅ AS9100/IATF 16949 uyum: audit-ready data tracking

✅ Heavy industry expertise: understanding coolant/fouling challenges

✅ Global scalability: multi-plant deployment capabilities

“5 RFID Strategies to Improve Machining Profitability”