Washable RFID tags are specially designed to withstand harsh environments such as washing, chemical cleaning and high-temperature disinfection. Such tags are widely used in textile management, medical and health, industrial manufacturing and other fields. Here are some key information about washable RFID tags:

- Materials and Design

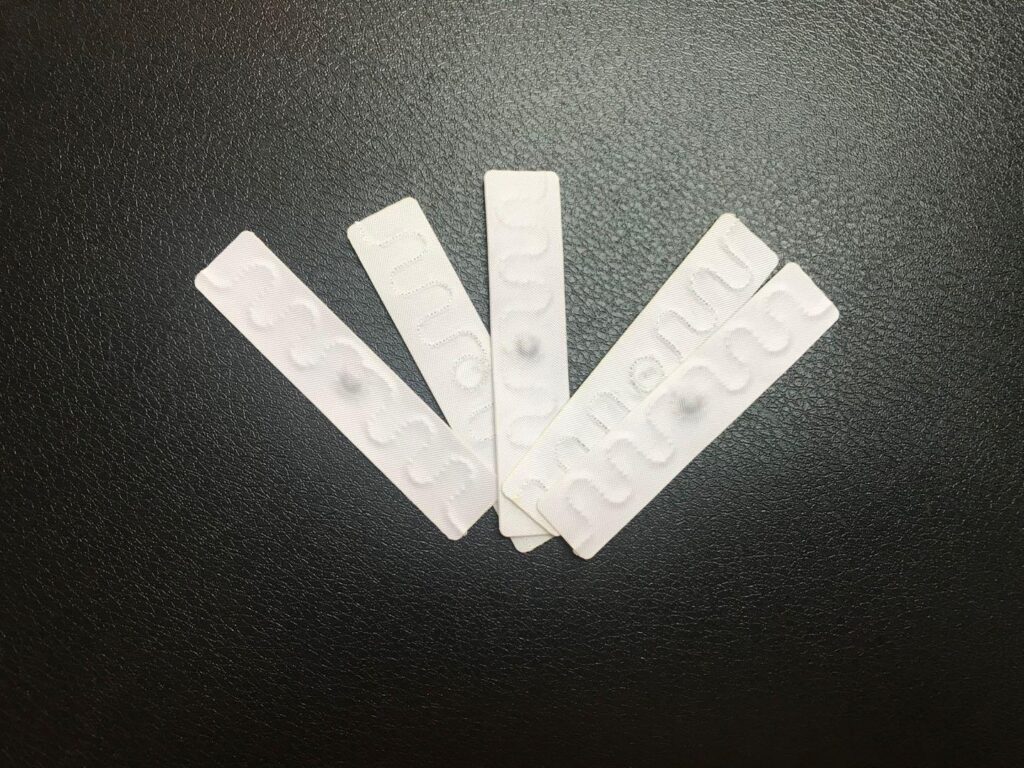

Packaging materials: High temperature and chemical corrosion resistant materials such as polyester (PET) and polyurethane (TPU) are used. Some tags also use silicone packaging to improve durability.

Packaging process: Ultrasonic welding, compression molding and other processes are usually used to ensure that the chip and antenna are not damaged in harsh environments. - Technical parameters

Frequency range: Usually works in the ultra-high frequency (UHF) range (860-960 MHz), suitable for long-distance reading; there are also those working in the high frequency (HF) range (13.56 MHz), suitable for close-range reading.

Storage capacity: Depending on the application requirements, the storage capacity ranges from a few hundred bytes to a few thousand bytes.

Reading distance: Depending on the antenna design and the power of the reader, the reading distance can range from a few centimeters to a few meters. - Application scenarios

Textile management: used to track and manage textiles in factories, laundries, hotels and other places. The tags can withstand multiple washings, high-temperature drying and ironing.

Health care: used for hospital linen management, surgical instrument tracking and patient identification, ensuring that the tags are not damaged during disinfection and cleaning.

Industrial manufacturing: used to track and manage workpieces and tools on the production line, adapting to cleaning and high-temperature environments. - Advantages

Strong durability: designed for a long life, can withstand hundreds or even thousands of washing and disinfection processes.

Reliable data: The data in the tag can remain stable in harsh environments, ensuring the accuracy and reliability of the information.

Easy to operate: can be read at a long distance, reduce manual intervention, and improve management efficiency. - Precautions for use

Installation location: When installing tags on textiles and equipment, select a location that does not affect use and is not easily damaged.

Washing conditions: Although the tag is designed to be resistant to high temperatures and chemical corrosion, it still needs to be operated according to the washing conditions recommended by the manufacturer in actual use.

Data security: Ensure the encryption and protection of tag data to prevent unauthorized reading and tampering.

In short, washable RFID tags play an important role in modern management, greatly improving the efficiency and safety of various industries by optimizing logistics, inventory and asset management.