In an age where food safety, Trazabilidad, and operational efficiency are critical, the food manufacturing industry is turning to advanced technologies like RFID to meet stringent regulations and consumer demands. RFIDHY is a pioneer in RFID solutions, providing RFID products (incluyendo Etiquetas RFID, Lectores RFID, and integrated systems) tailored to meet the unique challenges of food production, procesamiento de, and distribution.

The Role of RFID Tags in Modern Food Manufacturing

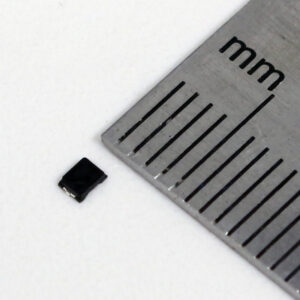

etiqueta rfid más pequeña

RFID tags have become an indispensable tool for ensuring transparency and compliance in food production. Unlike traditional barcodes, these tags store a wealth of data (such as batch numbers, Fechas de caducidad, and storage conditions), enabling real-time tracking from raw materials to finished products. Por ejemplo, in meat processing plants, Etiquetas RFID UHF (860-960 MHz) can monitor temperature-sensitive products, al mismo tiempo HF RFID tags (13.56 MHz) ensure accurate traceability of ingredients in baked goods.

Key benefits of RFID tags in food manufacturing include:

- Enhanced traceability: Track products across global supply chains, reducing the risk of recalls.

- Temperature Monitoring: Built-in sensors in semi-passive RFID tags alert teams to deviations in cold storage.

- Lucha contra la falsificación: Unique identifiers verify high-value items like organic ingredients or specialty supplements.

Optimize Operations with RFID Readers and IoT Integration

Lector HY-R6100

RFID readers are the backbone of data collection in food facilities. RFIDHY’s second-generation UHF RFID readers (902-928 MHz) offer long-range scanning capabilities, ideal for monitoring pallets in large warehouses. Paired with IoT sensors, these readers enable:

- Mantenimiento predictivo: Detect equipment anomalies in blenders or conveyors before they fail.

- Workflow Automation: Streamline packaging lines by syncing RFID readers with labelers.

- Compliance Reporting: Automatically log temperature and sanitation data to meet FSMA and GMP standards.

For environments that require mobility, handheld RFID readers enable workers to perform instant inventory checks or find mislabeled batches, minimizing downtime.

Tailored RFID Solutions for Every Production Stage

RFIDHY’s RFID solutions are designed to accommodate different food manufacturing needs:

Ingredient Management

Etiquetas RFID LF (125 kHz) track bulk ingredients like grains or spices in silos, ensuring accurate usage and reducing waste.

RFID-enabled scales automate portion control in snack production.

Processing and Packaging

NFC-enabled RFID tags on packaging machinery enable operators to access maintenance logs via smartphone.

UHF RFID antennas integrated into conveyor systems verify tag location and seal integrity.

Cold Chain Compliance

BLE-enabled RFID tags monitor refrigerated trucks, transmitting real-time data to a cloud platform for audit trails.

RFID printers produce durable tags that are resistant to condensation and frost.

Meeting Global Standards with RFID Technology

Compliance is non-negotiable in the food manufacturing industry. RFIDHY’s systems comply with the following key regulations:

- EPC global Gen2: Ensuring interoperability in global supply chains.

- GS1 Standards: Enhance traceability for USDA organic or EU Ecolabel certifications.

- FSMA Compliance: IoT-enabled RFID solutions automate hazard analysis and preventive controls.

Por ejemplo, dairy producers using HF RFID readers from RFIDHY can quickly trace contaminated batches back to specific milkings, streamlining recalls and protecting brand reputation.

Future Trends: Drones, IA, and Sustainable Practices

Innovations are reshaping the industry:

Drone-RFID synergy: Drones equipped with UHF RFID readers conduct aerial inventory checks in sprawling storage facilities, reducing manual labor.

AI-driven analytics: Machine learning algorithms analyze RFID data to optimize production schedules and reduce energy consumption.

Circular Economy: Reusable RFID tags on crates or containers support zero-waste initiatives.

Improve the safety, efficiency, and compliance of your operations with RFID solutions from RFIDHY. Explore our range of RFID tags, lectores, and IoT systems to build a smarter, more transparent food supply chain.