At present, there are more and more projects that require RFID tags to withstand high temperatures in industrial production. For example, food, electricity, steel and other special application environments have higher requirements for the heat resistance of the label. It is necessary to ensure that the label can provide stable feedback information in a high temperature environment, and the service life of the label must also be guaranteed. Today we will come Talk about the high temperature resistance of the Tag.

High-temperature resistant RFID tags refer to RFID electronic tags that can work stably and normally in a low temperature and high temperature environment. They are generally made of special materials. When making tags, special protective measures are used to make the chip, antenna, and reader of the product. The write distance is better protected to ensure that the label performance is not adversely affected by the temperature.

Polyphenylene sulfide (PPS) is commonly used in high temperature label materials. PPS is a kind of high rigidity crystalline resin engineering plastic with stable structure. It has the advantages of high temperature resistance, non-toxicity, flame retardant, chemical corrosion resistance, good insulation performance, etc., and can be stable for a long time. Below 240°C. It can be used in rigid and durable mechanical products; in electrical products that require heat and flame resistance; and can also be used in chemical devices that require corrosion resistance. Especially under the conditions of high temperature, high humidity and high frequency, it still has excellent electrical properties.

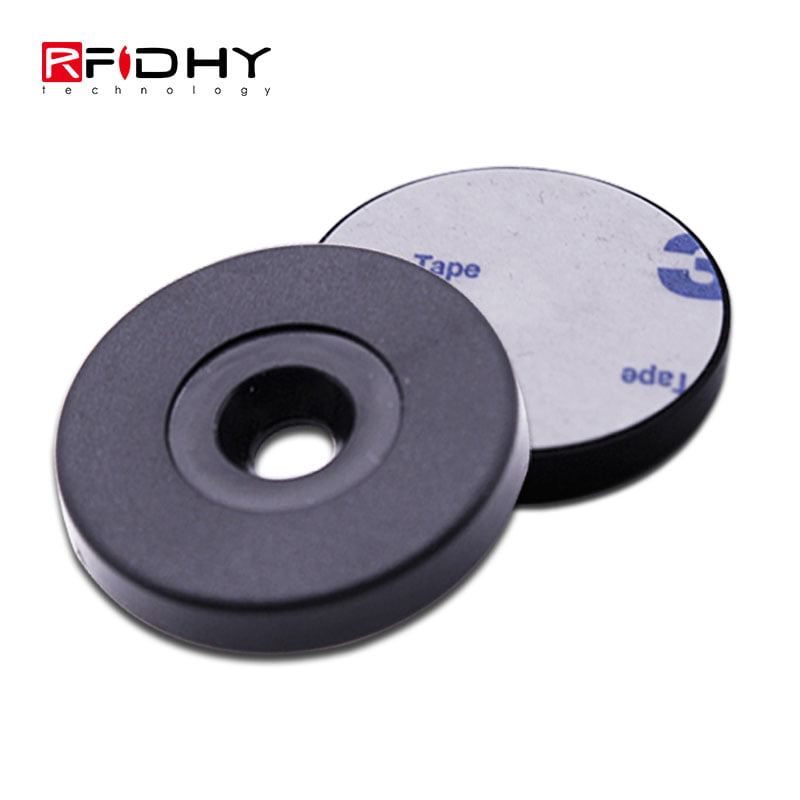

The electronic label encapsulated by PPS engineering plastic has many advantages such as high temperature resistance, flame retardancy, chemical corrosion resistance, high rigidity and wear resistance, and can be used in harsh environments with high temperature, high humidity, abrasion resistance, and corrosion resistance, such as laundry Many electronic tags are used in shops, car engine maintenance signs, chemical raw materials tracking, and many other applications.

Several parameters that affect label performance

1. Time and temperature indicators:

◆ The temperature resistance range of RFID tags indicated in general product specifications, but sometimes does not indicate the time when the RFID tag can be exposed to the highest (low) temperature. Many RFID tags can withstand extremely high temperatures for a short period of time, but if they exceed a certain period of time, the tags will fail.

◆ Therefore, for the application of high temperature and high pressure steam sterilization, the time that the label can withstand high temperatures must be fully considered. For example, in the jet baking application used to track the chassis of a car, the label is required to be able to withstand exposure to high temperature for a long time.

2. RFID tag installation method:

◆ In high-temperature applications, adhesives are often one of the reasons for project failure. High temperature will cause the adhesive to fail and the label will fall off the device. In order to avoid this kind of situation, you should use a firmer installation method, such as high temperature resistant adhesive or epoxy glue, or weld the label on the device, or even directly embed it inside the product. In this way, you only need to make a corresponding size on the product.的槽。 The groove. If the label itself is designed with holes, you can also use screws, loops or ropes to fix it.

3. Interference factors on site:

◆ RFID tags use non-contact communication and are suitable for various special operating occasions. They are not affected by water stains, oil stains, and chemicals. However, if they are installed near a strong magnetic field such as a frequency converter or a motor, they will be severely disturbed. In order to avoid magnetic fields Interference, it is necessary to fully consider its installation location and electromagnetic shielding treatment for strong magnetic field equipment.

◆ In harsh environments such as special operations, two-dimensional codes and any printed labels cannot work properly to meet operational requirements. Only RFID tags are competent, even if they are affected by flames, smoke, oxidation or chemical reagents, they can work normally. , Read the data to ensure that the information will not be damaged in harsh environments.