In the logistics distribution center, large-scale intelligent sorting equipment is constantly running. These “smart” machines accurately deliver packages from all directions according to whereabouts, and combine packages of different sizes according to a certain ratio, and then concentrate them. Load the truck so that the cargo space can be used reasonably. With smart devices as a helper, one person is a “threatening army”, which greatly improves logistics efficiency. The LGS/LGM smart grating for sorting goods is just a “good helper” for efficient and speed-up in logistics applications, allowing users to easily determine the size of goods and realize automatic sorting.

1. Application challenges

Packages vary in size, and if they are arranged in a disorderly manner, a lot of unusable space will be left when packing. Goods that could be loaded by one truck are now required to use two, which greatly increases the transportation cost. Manual sorting is not only time-consuming, labor-intensive and costly, but also error-prone, and it is not a wise choice.

2. Solution

The LGS detection type grating with high switching signal output and the LGM measuring type grating with direct output of the measured value can reliably distinguish goods of different sizes and perfectly solve the sorting problem.

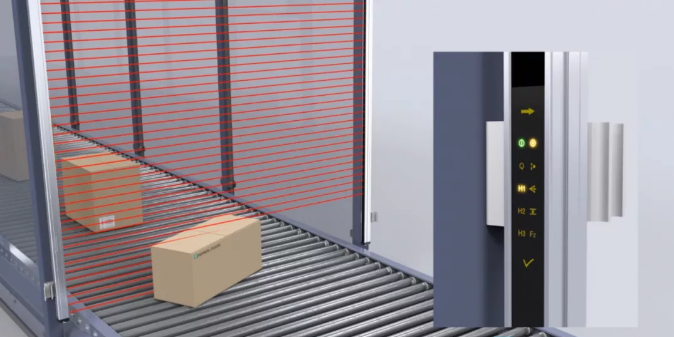

3. Application 1: Height output

LGS has 3 high-level outputs, which can directly distinguish large, medium and small packages with three different specifications. The switch signal is directly connected to the input of the controller, which is easy to use. The three-way height output can be quickly set through the touch screen display on the panel. What if 3 is not enough, don’t be afraid, the system comes with an IO-Link interface. In IO-Link mode, the process data contains 8 height output bits, which means that you can now configure 8 heights to achieve a more refined size distinction. .

4. Application 2: Measurement data

What is the specific size of the package and how to measure it? This is a good time for LGM measuring gratings to show their talents. LGM transmits the real-time measured value to the control terminal through the IO-Link connection, and the size of the goods is obtained by the controller at the moment it passes through the grating. After that, the controller allocates the correct transmission route for the goods and flows to the corresponding logistics area. The LGM’s three-beam crossover function can achieve a resolution of up to 4mm, which is more than enough for cargo size measurement.

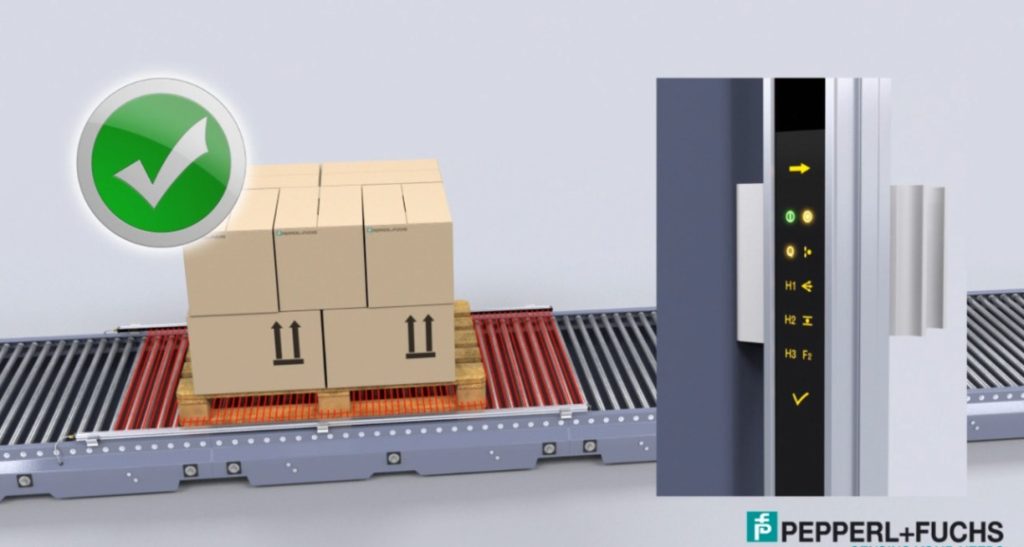

5. Application 3: Object recognition

Some goods will be stacked on the pallet, how to identify the pallet is also a big challenge. However, in the face of LGS/LGM, these are a piece of cake. The grating has one object recognition output, the grating is arranged horizontally, and the three-beam cross function is turned off. After teaching the tray, the shape of the tray is memorized by the grating. When the tray with the same characteristics passes through the grating, the corresponding beam is blocked. It immediately sends an identification signal to the controller to tell the controller to recognize the tray. Of course, different pallet feet will have a tolerance range. LGS/LGM allows more or less shielding of a beam during the identification process, which improves the reliability of identification.